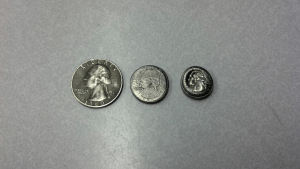

The below image shows US quarters, deformed electromagnetically. Interestingly, all of the minted features are preserved! Though it is fun headline to use the term “shrink”, matter is conserved in this process and the density does not change. Note: the second in from the left (below) does not have the features preserved – this is discussed later.

Introduction

I studied magnetic pulse welding (MPW) for my master’s thesis at University of New Hampshire. The MPW process cold welds metals together at high velocities created by a magnetic pulse. At lower energy levels, workpieces can also simply be formed, and this is known as electromagnetic forming (EMF).

The magnetic pulse is created by discharging a high voltage capacitor bank into a coil, which in turn creates eddy currents in the workpiece. Lorentz forces between the current in the coil and eddy currents in the workpiece propel the workpiece at high speeds (100-300m/s).

https://www.fabricatingandmetalworking.com/2008/04/filler-wire-is-for-wimps/

Due to the high speeds involved, the metals can be deformed to a higher extent (larger strains) from the stability generated by inertial forces.

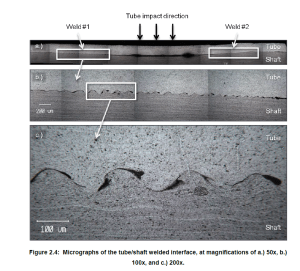

Aside: In the weld interface a wavy interface typically results, which I showed in my thesis:

https://scholars.unh.edu/thesis/826

Setup

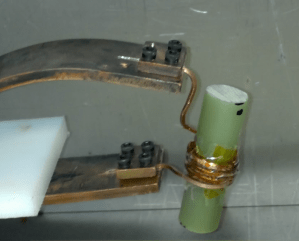

The setup to shrink a quarter consists of a disposable coil created by wrapping a few turns of magnet wire around a insulating mandrel made of FR4. The mandrel has two coaxially located conical holes to allow for the quarter to displace axially.

Interestingly, my first attempt at shrinking a quarter did not preserve the minted features (below, center). I was missing the holes described above, which did not allow the quarter to expand axially outwards. Even though the two insulated mandrels are only lightly taped together, it is the inertial force keeping the assembly together long enough to not allow the quarter to expand.

The assembly is then inserted into a safety box made from 0.5in thick aluminum, and the ends of the coil are attached to the leads of the capacitor bank:

Aftermath

Only tiny bit of the magnet wire are left:

But not only are the magnet wire fragments scattered around, but some are embedded into the aluminum:

Below is an image showing the blue capacitor bank. This is a commercial unit from Maxwell Magneform with a charge capacity of 12kJ. Though, these quarter shrinking experiments are run at much less than full capacity: