Purpose

This kegorator was built to serve home brewed & commercial beer, and seltzer. An added benefit is that kegging home brewed beer directly is much easier than individual bottling.

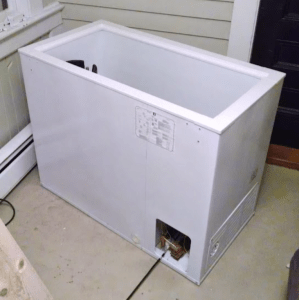

The kegerator is built from a chest freezer, repurposed to run at a higher temperature with an external controller. A CO2 tank, manifold, and regulator provide propulsion for the beer as well as keep it carbonated. Draft beer faucets act as valves to serve the beer.

Hardware

A chest freezer provides the cooling, which has a capacity of 8.8 ft^3. A important goal of this build was to only perform reversible modifications to the freezer so that it could be resold (e.g., to replace with a larger unit, or sell if interest fades).

Before purchasing the chest freezer, the internal dimensions were checked by creating a layout drawing, and ensuring three homebrew ball lock kegs or 1/6bbl. commercial kegs could fit. It’s important to note that this is the space on the floor of the freezer, not including the bump where the compressor is housed.

The lid and hinges were removed and the unit was thoroughly cleaned (it was still smelling like dog food).

A 2x6in wood collar allows for the tap handles to pass through without having to drill holes in the the freezer. Not only does this leave the freezer intact, but also eliminates the risk of accidently drilling through condenser coils. The hinges were then remounted to the collar, which rests on the body of the freezer with 1/2in. adhesive backed insulation on the bottom. The original lid seal was left intact to seal the top of the collar.

Beers shanks pass through the wood collar, and allows for mounting of beer lines and faucets.

providing a mounting point for the taps.

Showing three commercial kegs.

An Engineering Aspect

Performance was not great with the initial build. Beer would either pour too quickly (CO2 pressure too high), or the beer would go flat over time (CO2 pressure to low).

To fix this, a common trick was applied: Increase the tubing length from the keg coupler to the faucet. By increasing the tubing length, the CO2 pressure can be raised to keep the beer carbonated. But since the flow resistance is now higher, the beer will flow at the correct speed. About 5ft of extra line created the correct balance, which was simply coiled up inside to provide the extra resistance.